Driving the Future of Precision Manufacturing

At BTX, we're more than just a network of advanced manufacturing organizations — we're a strategic partner to some of the world’s most innovative and demanding brands.

Our mission is to accelerate technological advancement by aligning the right manufacturing infrastructure with leading companies in the most dynamic and durable end markets, for the most complex and mission-critical needs.

BTX at a Glance

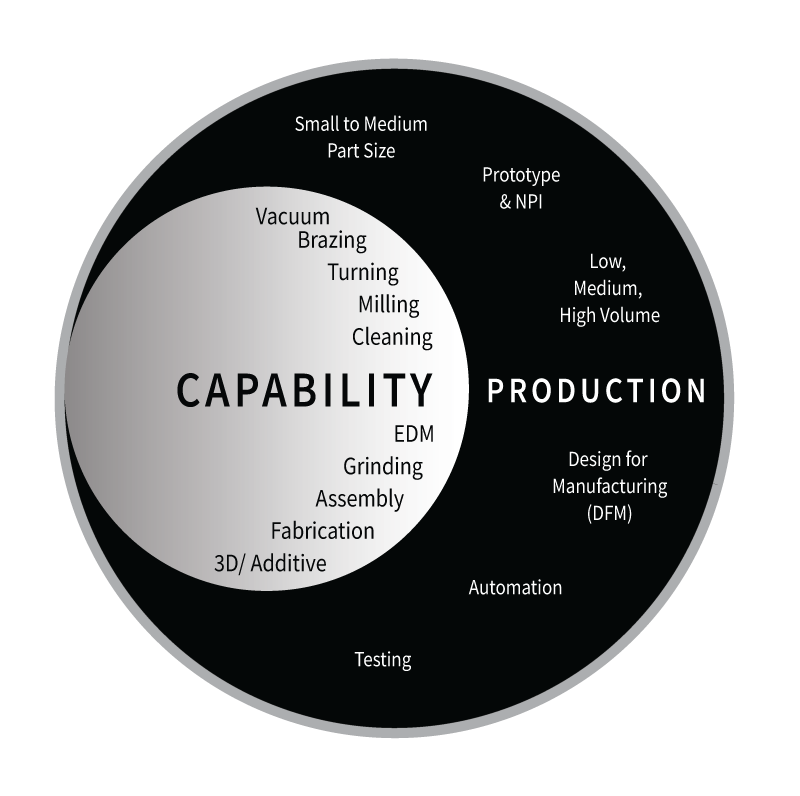

At BTX Precision, our value lies in the intersection of broad capability and scalable production.

Whether you’re developing prototypes or scaling to high-volume output, our vertically integrated organizations support every phase — with advanced automation, design for manufacturability (DFM), and rigorous quality controls. Trusted across aerospace, defense, medical, semiconductor, transportation, and industrial sectors, BTX delivers mission-critical components with precision and speed.

By the Numbers

A look at the scale, speed, and strength behind BTX’s precision manufacturing network.

Manufacturing Locations

9 States, 13 Cities

![]()

Manufacturing Space

700,000 sq. ft.

![]()

Employees

1,150+

![]()

3D Printers

30+

Milling

400+

![]()

EDM Machines

50+

![]()

Grinding Machines

100+

![]()

Turning Centers

220+

Growth Model

The BTX Growth Model is designed around six strategic elements. Each reinforces the others to create a sum greater than its parts.

1. Strategic Acquisitions

Profitability enhancement via operational and commercial excellence feeds an acquisition strategy focused on highly differentiated businesses that expand our service offering to our target markets, leveraging our growth model to achieve long-term sustainable success.

2. Multi Brand Strategy

Allows for Broader market penetration and caters to diverse customer preferences, while fostering healthy internal competition. Each brand fosters its own unique brand and identity.

3. Operational Excellence

While each business unit maintains its own operations, BTX integrates a culture of continuous improvement with lean principles across our business units to ensure all operate consistently, adopting best practices where sensible, to enhance manufacturing efficiency.

4. Capital Allocation

In pursuit of lean we continuously invest in technology and automation. This is why CAPEX is aligned relative to each business units performance optimization plans (POP), rolled up to the parent and awarded on goal completion percentage.

5. Intercompany Synergies

We leverage intercompany synergies by integrating expertise, technology, and resources across our business units to drive efficiency, quality, scalable growth and profitability

6. Commercial Alignment

Sales teams partnering together, squarely focused on customer continuity and maximizing cross-selling opportunities that enhance customer satisfaction across all business units.

Certified Quality, Built into Every Process.

We adhere the highest standards of quality control and security, maintaining ISO9001, AS9100D, ITAR, and CMMC compliance, to ensure that dimensional accuracy, material integrity, and regulatory requirements are not only met but surpassed.

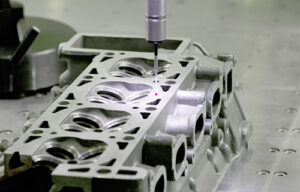

Every Part Inspected. Every Standard Met.

Our in-house quality labs, advanced CMM systems, and rigorous inspection protocols ensure every component meets exact specifications, industry certifications, and customer expectations — every time.

CMM Inspection

CMM Final Inspection

Quality Lab

Quality Inspection

What sets us apart?

We’re built to keep your production running — reliably, efficiently, and on time

![]()

Peace of Mind, Built In.

BTX organizations operate under some of the most demanding standards in manufacturing — so our customers can focus on innovation.

Quality Certifications: We maintain the most demanding quality across our business units, including ISO9001, AS9100, and Nadcap, ensuring adherenece to the rigorous QA standards our customers demand.

Controlled Environment: State of the Art: Modern super clean 5S manufacturing environments with pristine surfaces, advanced air filtration, and automated systems that ensure precision, efficiency, and contamination-free production.

Compliance: Registration and compliance with both ITAR and CMMC underscores BTXs dedication to security and compliance.

![]()

Risk Mitigation at Scale

In today’s volatile world, continuity is critical. BTX is built with the infrastructure to minimize risk — so your supply chain stays strong.

Manufacturing Scale: Production manufacturing scale that relieves costs associated with production delays.

Optionality: Added production capacity can serve as pressure-release valves to manage market volatility and new product expansions.

Redundancy: Multiple manufacturing locations mitigate the impact of regional disruptions, such as natural disasters or geopolitical issues, ensuring continuity in production and supply chain operations.

![]()

Simplified Vendor Management

Working with BTX means more than just quality parts — it means fewer headaches, more value, and stronger partnerships.

Cost Efficiency: Fewer vendors lead to economies of scale and enhanced synergies that reduce nonvalue-added time and procurement costs.

Simplified Management: Managing fewer relationships simplifies communication, coordination, and quality control, ensuring consistency across components.

Stronger Partnerships: Consolidating vendors foster stronger, more collaborative relationships, improving communication, responsiveness and overall service levels.

Capabilities At a Glance

From advanced CNC milling to complex assemblies, these are the capabilities that set BTX Precision apart.