Precision Grinding and Lapping for Critical Applications

BTX Precision offers a full suite of manual and CNC grinding services designed to deliver tight-tolerance finishes, complex profiles, and ultra-flat surfaces across a wide range of materials

Precision Grinding for Critical Applications

From small prototype runs to full production volumes, our grinding capabilities support the precision demands of industries including aerospace, medical, defense, energy, and semiconductor. Whether it’s flatness, roundness, surface finish, or dimensional control, BTX delivers grinding solutions that meet the highest performance standards.

State-of-the-Art Equipment for World-Class Grinding

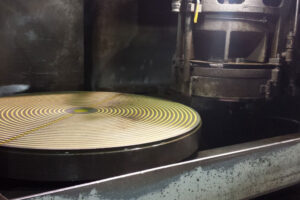

Blanchard Grinding

Surface Grinding

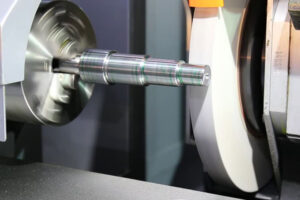

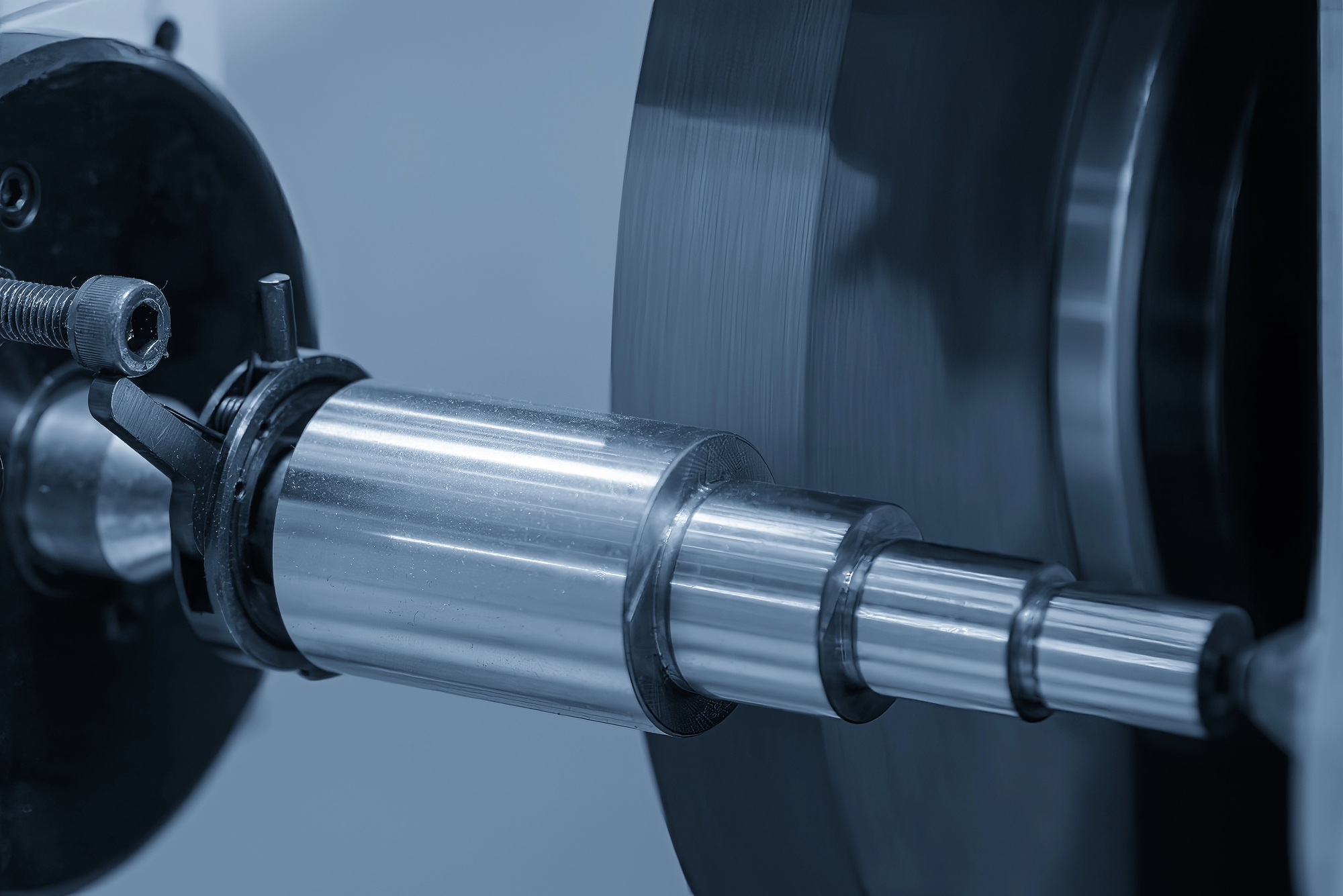

OD Grinding

Comprehensive Grinding Capabilities

Our grinding operations are equipped to handle both external and internal geometries with extreme accuracy. We offer a range of precision processes to ensure every part meets its critical specs — even on hard or thermally sensitive materials.

Our grinding capabilities include:

-

Surface Grinding for ultra-flat finishes and high precision

-

OD (Outer Diameter) Grinding for concentricity and roundness

-

ID (Inner Diameter) Grinding for bore sizing and finishing

-

Thread Grinding for high-accuracy thread profiles

-

Jig Bore Grinding for fine-tolerance bores and hole locations

-

Blanchard Grinding for efficient material removal on large parts

-

Double Disc Grinding for tight flatness and parallelism

-

Lapping for superior surface finish and dimensional control

-

Multi-Axis CNC Grinding for complex contours and ultraprecision features

-

Height Masters & Metrology for real-time measurement and in-process feedback

Lapping

Lapping machines are a type of precision finishing machine used to create truly flat surfaces, normally up to 0.001mm, with surface finishes of better than Ra.01. Overall, lapping produces extreme dimensional accuracy, corrects minor imperfections of shape, refines surface finish, and produces close fit between mating surfaces.

Lapping is ideal when absolute flatness, parallelism, or fine surface finish is needed. This loose abrasive process easily handles irregular or non-magnetic parts, removes stock quickly without clamping, heat distortion, or costly tooling, and requires minimal maintenance. It lowers inspection and production costs and works well for both small batches and high-volume runs.

Complex & Mission-Critical Applications

Aerospace & Defense

Precision bushings, bearing surfaces, and structural interfaces

Medical

Surgical tools, implantable hardware, and orthopedic components

![]()

Semiconductor

Polished fixtures, tooling plates, and vacuum surfaces

Space

Flight-ready fasteners, opto-mechanical features, and lightweight mounts

Built for Consistency at Any Volume

Whether you're producing a single precision washer or hundreds of matched sets, BTX offers grinding solutions built to scale. Our combination of automated systems, skilled operators, and controlled processes ensures part-to-part consistency across all production runs.

- Flexible capacity for short-run and high-volume production

- Repeatable performance through advanced CNC programming

- In-process inspection and documented measurement

- Integration with upstream machining and finishing operations

Start Your Grinding Project with BTX

Proudly Made in the USA | Responsive. Reliable. Precise.