Metal 3D Printing for Complex Parts

BTX Precision offers additive manufacturing solutions via Direct Metal Laser Solidification (DMLS) for components that require complex internal geometries, weight reduction, or rapid development.

Advanced Metal 3D Printing with DMLS® Technology

We utilize advanced additive manufacturing platforms to produce high-performance metal components with complex geometries. By employing DMLS technology and carefully selected metal powders optimized to customers specifications, along with rigorous quality assurance processes, we ensure the reliable production of mission-critical components

30+ DMLS Machines

Maximum Travel: 15.7x15.7x15.7”

Part Tolerances: 0.005” - 0.010”

Sectional Tolerances: down to 0.002”

Premium Metal Powders for High-Performance Parts

i3D MFG uses a wide range of advanced metal powders in its Direct Metal Laser Solidification (DMLS) 3D printing to produce high-performance parts for aerospace, medical, and industrial applications. These powders are selected for their strength, corrosion resistance, thermal performance, and material-specific benefits.

Powders used include:

- Iron-based

- Nickel-based

- Cobalt-based

- Copper-based

- Aluminum-based

- Titanium-based

- Stainless-based

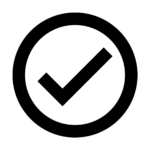

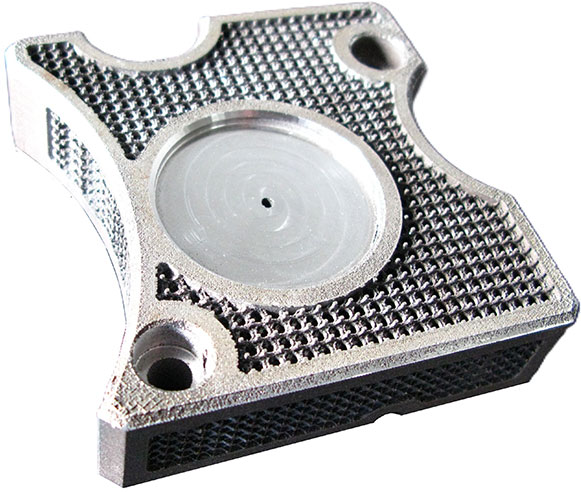

Design Freedom with DMLS®

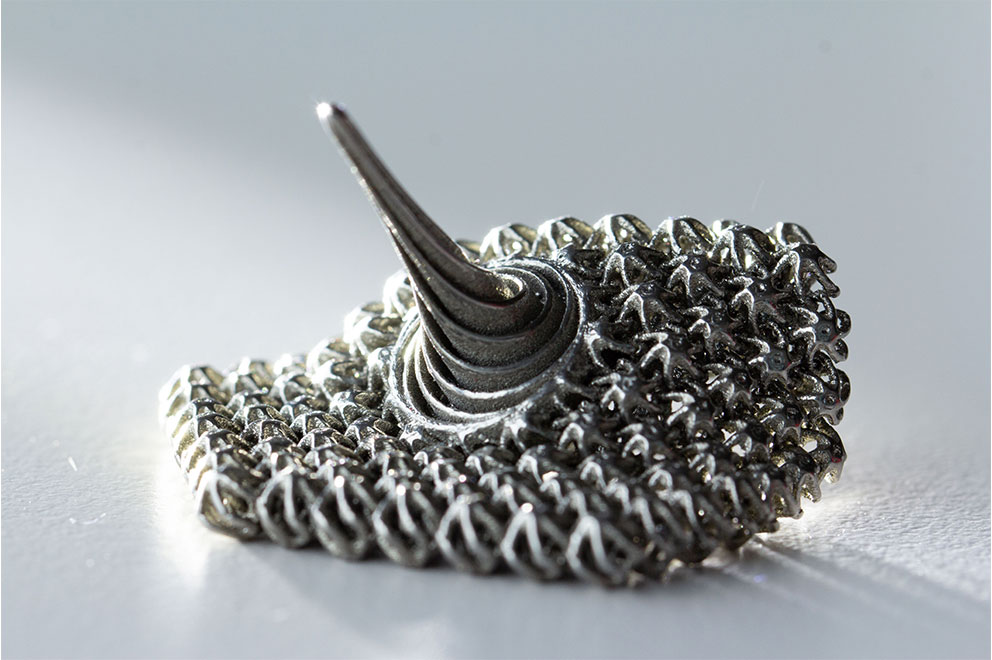

Direct Metal Laser Solidification (DMLS) builds parts layer by layer, using high-powered lasers to fuse fine metal powders. This allows us to create complex features — including internal channels, lattice structures, and undercuts — that would be difficult or impossible to machine conventionally.

DMLS enables:

- Near-net shape parts with minimal post-machining

- Integrated features that reduce part count and weight

- Improved strength-to-weight performance

- Design optimization for fluid flow, cooling, and thermal management

- Accelerated product development timelines

Complex & Mission-Critical Applications

Aerospace & Defense

Lightweight mounts, ducting, and flow-optimized housings

Medical

Surgical guides, porous structures, and titanium implants

![]()

Semiconductor

Semiconductor vacuum hardware and alignment pins

Space

Lattice brackets and thermal control housings

Production Technology That Scales

Our additive manufacturing platforms are built for more than just prototyping. With repeatable processes, automated powder handling, and post-processing integration, we deliver metal 3D printed parts that meet demanding production standards — at scale.

- Consistent build quality across batches

- Multi-machine capacity for faster throughput

- Integrated post-processing (support removal, heat treatment, machining)

- Ideal for bridge production or high-mix, low-volume runs

- Accelerated lead times vs. traditional manufacturing

Start Your Additive Manufacturing Project with BTX

Proudly Made in the USA | Responsive. Reliable. Precise.