Aerospace Manufacturing Solutions

Precision Components. Proven Performance.

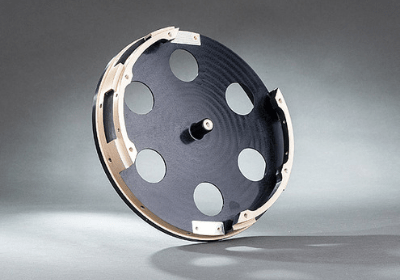

Haynes 282 Rocket Chamber

At BTX Precision, we provide advanced manufacturing solutions for the aerospace industry, delivering tight-tolerance components that meet the rigorous standards of flight.

Our family of organizations supports everything from commercial aviation and defense aerospace to space propulsion and satellite systems, offering the scale, quality, and technical expertise.

Aerospace Materials Expertise

Our in-depth knowledge of material behavior during high-speed machining ensures part consistency, reduced waste, and shorter lead times.

We machine aerospace-grade materials daily, including:

- High-Strength Steels (e.g., 4340, 300M, HY-80) – Used in structural components, armor, and aerospace-grade systems

- Titanium Alloys (e.g., Ti-6Al-4V) – Lightweight, corrosion-resistant, and strong; ideal for aircraft, naval, and missile systems

- Aluminum Alloys (e.g., 7075, 6061, 7050) – Lightweight and machinable; used in aerospace frames, electronics housings, and weapons systems

- Stainless Steels (e.g., 17-4 PH, 15-5, 316L) – Corrosion resistance and strength; used in naval, aerospace, and weapon components

- Nickel Alloys (e.g., Inconel 718, Monel, Hastelloy) – High performance in extreme temperatures and corrosive environments

- Copper Alloys (e.g., C110, CuBe, bronze) – Excellent conductivity; used in electronics, radar systems, and thermal applications

- Engineering Plastics (e.g., PEEK, Ultem, Delrin) – Used for insulation, lightweight components, and EMI/RFI shielding structures

- Aerospace Composites (e.g., Carbon Fiber, Kevlar, Glass Fiber) – Lightweight, high-strength materials ideal for structural and aerodynamic applications

Common components include:

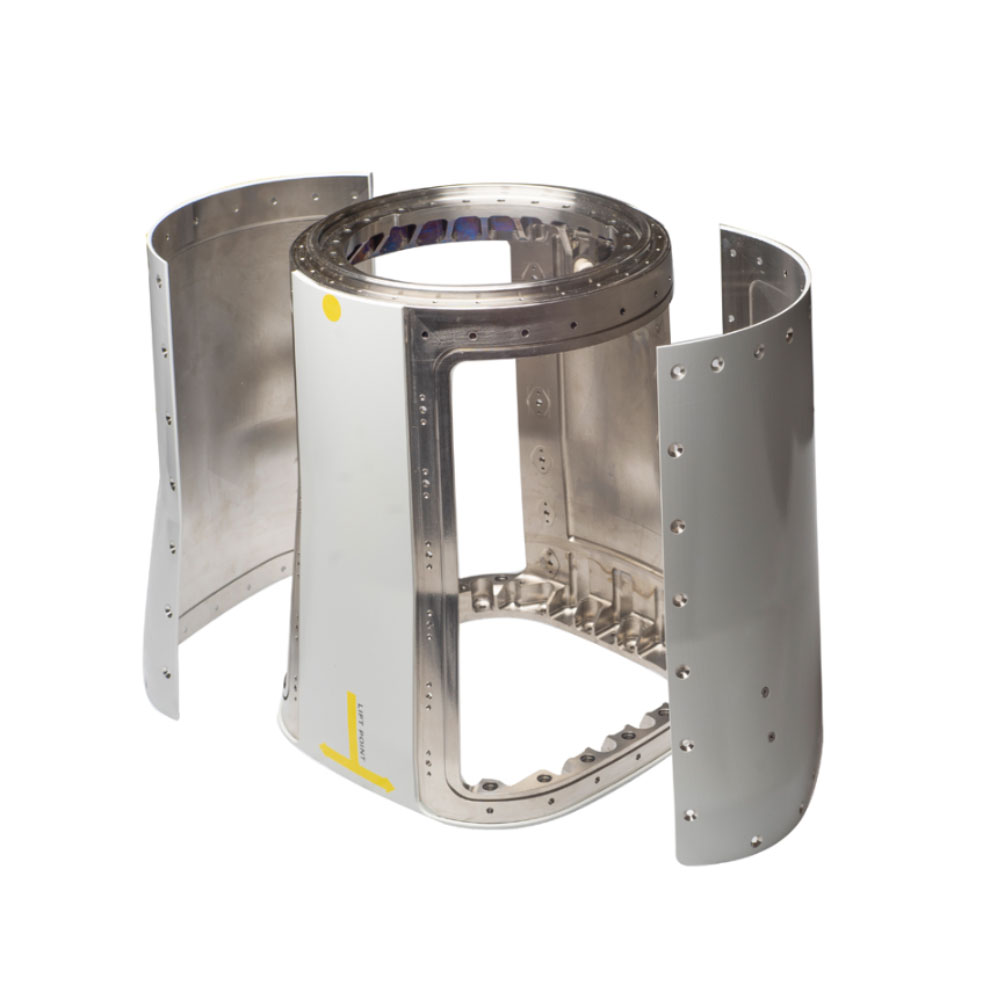

- Engine and turbine housings

- Brackets, clamps, and structural supports

- Sensor housings and enclosures

- Actuation system parts

- Ground support and test equipment

- Custom fasteners and machined fittings

- Satellite and space propulsion components

Components We Commonly Produce for Aerospace

BTX Precision companies manufacture a wide range of flight-critical and supporting components.

Certified to Perform at the Highest Level

From AS9100D to ITAR, our certifications demonstrate the quality, traceability, and reliability that mission-critical industries demand.

Essential Manufacturing Capabilities for Aerospace Industry Components

- Precision Milling – Required for tight tolerances on structural, engine, and flight-critical components

- Mill-Turn and Swiss CNC Machining – For producing intricate, multi-feature parts in fewer setups to ensure accuracy

- Certified Welding & Assembly – Aerospace-grade TIG, MIG, and laser welding for structural and pressurized assemblies

- Surface Treatments & Coatings – Anodizing, alodine, shot peening, and hard coatings for corrosion and wear resistance

- Advanced Inspection & Quality Systems – CMM, laser scanning, and non-destructive testing with AS9100 and NADCAP compliance

- Full Traceability & Documentation – Lot control, FAI, PPAP, and conformance to aerospace standards (FAA, DoD, OEM specs)

Start Your Next Aerospace Project with BTX

Whether you're sourcing precision aerospace components or need a certified aerospace manufacturing partner, our oergsanizations have the tools, talent, and technology to deliver.

![]()

ERA brings 5 Axis and Horizontal milling with multi pallets for dedicated set ups and lights out machining capabilities, offering turning, milling, brazing, EDM, assembly and grinding.

![]()

Gen-El-Mec Associates specializes in complex milling and turning for prototype, short-run and long-run production utilizing innovative machining techniques, state of the art equipment and stringent quality control.

![]()

i3DMFG specializes in additive manufacturing, particularly Direct Metal Laser Solidification, with expertise and capacity to support both development and production requirements.

![]()

A1J Technologies is a one-stop machine shop specializing in precision machining, advanced laser applications, and rapid-turnaround parts cleaning.

Chandler Industries combines precision machining with sheet metal fabrication, welding, complex assembly, and other processes to deliver comprehensive solutions.

![]()

Addison Precision Manufacturing is a top-tier contract manufacturer that excels in producing high-precision machined components.

Built for the Demands of Aerospace

Aerospace machining requires absolute precision — and that’s exactly what we deliver. From structural assemblies and housings to complex 5-axis milled components and turned parts, BTX companies are built to handle: everything from commercial aviation and defense aerospace to space propulsion and satellite systems, offering the scale, quality, and technical expertise trusted by leading OEMs and Tier 1 suppliers.