Integrated Assembly Solutions for Complex, High-Reliability Systems

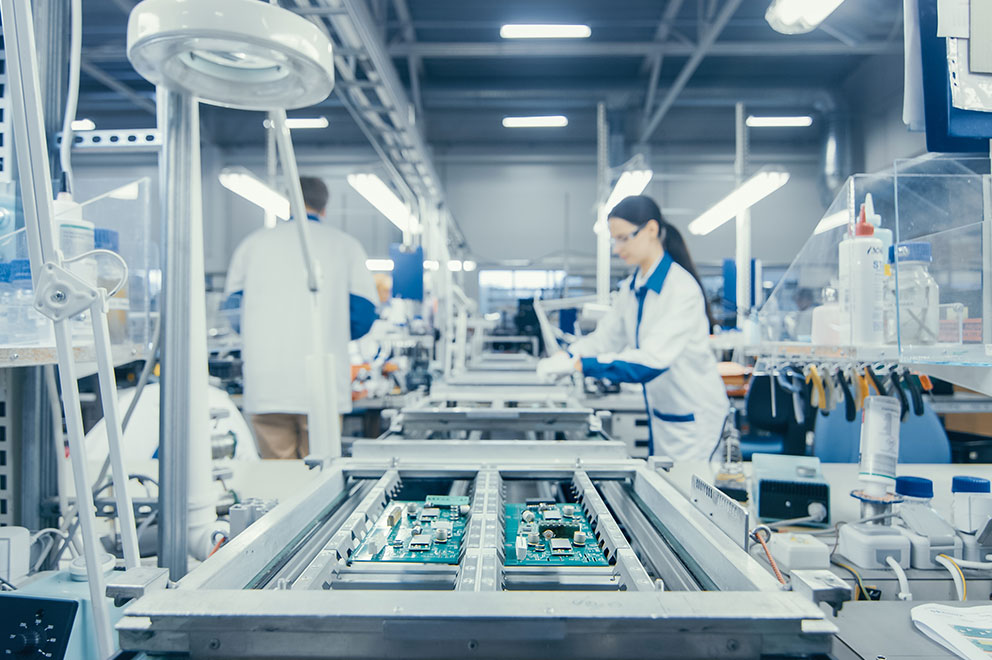

BTX Precision offers fully integrated assembly capabilities to support complex mechanical, electromechanical, and structural systems.

Assembling Precision. Delivering Confidence.

BTX Precision offers fully integrated assembly capabilities to support complex mechanical, electromechanical, and structural systems. Whether you're building aerospace subassemblies, surgical instruments, or industrial control units, we combine precision processes with scalable workflows to deliver complete, tested assemblies that meet your most rigorous requirements.

From cleanroom environments to precision fastening and micro-deburring, our assembly teams ensure every component comes together with care, consistency, and compliance.

Equipment & Capabilities Overview

Assembly Services

BTX offers a wide range of precision assembly services, including mechanical and structural assembly, electromechanical integration, and cleanroom-certified processes within ISO Class 7 and 8 environments.

Inspection & Testing

Each assembly undergoes comprehensive quality checks, including functional testing, dimensional verification, and visual inspection. We also provide full documentation, serialization, and traceability reporting to meet the rigorous standards of regulated industries.

Support Services

To streamline your supply chain, BTX offers end-to-end support services such as kitting, labeling, and final packaging. We also support advanced inventory strategies, including Kanban, Just-in-Time (JIT), and Vendor-Managed Inventory (VMI).

End-to-End Assembly Capabilities

BTX organizations are equipped to manage both partial and full-system assemblies, with robust in-process controls, traceability, and documentation throughout the build process. We offer value-added services that reduce supply chain complexity and improve quality by integrating assembly directly into the manufacturing workflow.

Our capabilities include:

- Full-system and subassembly integration

- Mechanical and electromechanical assembly

- Precision bonding and fastener installation

- Micro-deburring and part cleaning

- Labeling, marking, and serialization

- Packaging, kitting, and shipping

Assembly for Complex & Mission-Critical Industries

Aerospace & Defense

Flight hardware, mounts, and avionics enclosures

Medical

Surgical assemblies, housings, and instrument subassemblies

![]()

Semiconductor

Tooling frames and contamination-sensitive modules

Space

Lightweight structural brackets and ground support assemblies built for vacuum, vibration, and launch conditions.

Cleanroom Assembly & Contamination Control

For industries requiring the highest levels of cleanliness and process control, BTX offers ISO-class cleanroom assembly environments. These facilities are ideal for applications in medical, semiconductor, and space industries where contamination can compromise performance or safety.

- Clean, controlled environments for sensitive components

- Surface prep, packaging, and inspection under cleanroom conditions

- Operator training and process documentation aligned to industry standards

- Support for FDA, ISO 13485, and AS9100 programs

- Up to ISO6 Class 10,000 Certified Environments

Start Your Assembly Project with BTX

Proudly Made in the USA | Responsive. Reliable. Precise.