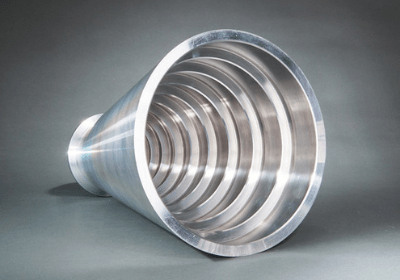

Custom CNC Machining Services of Aerospace Aluminum Housings

Gen-El-Mec Associates, Inc. specializes in complex machining of precision products for the aerospace industry.

We manufactured these aluminum housings exactly to the customer’s specifications. Machined from solid aluminum billet, it featured dimensions of 8.50″ in diameter and 13.13″ in height. Utilizing high-tech CNC machine tools combined with well-engineered manufacturing strategies, we were able to effectively maintain the .040″ wall thickness and cut the highly intricate edge details of the internal flanges.

Our metrology technicians used a high accuracy CMM system to take precision measurements at all critical stages, and final inspection substantiated that we met the ±.0005″ tolerance requirement. This high-performance housing was delivered to the customer within a 10-week timeframe. If you would like to learn more about this project, or how our ability to craft complex, high-value components can improve your next project, contact us today.

CNC Machining of Aluminum Housings Project Highlights

| Product Description | Industrial manufacturing of aluminum housings for a customer in the aerospace industry |

| Capabilities Applied/Processes | Primary: CNC Machining Services |

| Equipment Used to Manufacture | CNC Lath CNC Vertical Milling Machine |

| Overall Part Dimensions | Diameter: 8.50 Height: 13.13″ |

| Tightest Tolerances | ±.0005″ |

| Material Used | Aluminum |

| In Process Testing/Inspection Performed | Zeiss CMM utilized to do in process and final inspection |

| Industry for Use | Aerospace Industry |

| Delivery/ Turnaround Time | 10-Week Delivery |

| Delivery Location | Danbury, CT |

| Standards Met | Customer Specifications, 2D CAD Drawing |