Precision Manufacturing for Power and Energy Systems

Manufacturing precision components for traditional and renewable energy systems

Aluminum Bracket

BTX Precision delivers critical components for energy technologies that power the world forward.

From traditional power generation to renewable infrastructure and emerging energy technologies, our network of advanced manufacturing organizations supports high-performance parts that demand precision, reliability, and durability. Whether you're building for energy storage, oil & gas, nuclear, or renewables, BTX brings the expertise, scale, and material capability to support your mission — safely and efficiently.

Energy Components We Support

BTX supports the manufacture of a wide range of build-to-print components for both traditional and renewable energy systems. Our teams produce tight-tolerance parts that integrate into turbines, fluid control systems, battery enclosures, and infrastructure hardware.

Typical components include:

-

Compressor housings and fluid manifolds

-

Thermal control plates and cooling assemblies

-

Valve bodies, flanges, and sealing components

-

Gearbox and drivetrain components

-

Enclosures for grid and storage systems Nuclear-rated subassemblies and brackets

- Nuclear-rated subassemblies and brackets

Common materials include:

-

Inconel, Hastelloy, and other HRSAs

-

Stainless steels (17-4, 316, 15-5, etc.)

-

Titanium and titanium alloys

-

Aluminum and aluminum alloys

- PEEK, Ultem, and high-strength polymers

Materials Expertise for Energy Applications Support

We routinely machine and fabricate components using materials engineered for thermal, chemical, and mechanical resistance — ideal for high-demand energy environments.

Built for Compliance. Proven in the Field.

BTX organizations maintain ISO 9001 and AS9100D certifications, with ITAR registration and full traceability to support regulated energy applications — including nuclear, defense-adjacent, and export-controlled programs.

Energy-specific Capabilities

- Precision Milling – Vertical, horizontal, and 5-axis CNC milling for large-scale and mission-critical components used in turbines, pumps, housings, and structural systems, with exceptional flatness, parallelism, and geometry control.

- Multi-Axis Turning – High-torque turning for both small and oversized parts, supporting components such as valve bodies, impellers, and pressure-retaining elements in high-pressure or corrosive environments.

- EDM Machining – Wire and sinker EDM for extreme-precision features in hardened alloys and superalloys, ideal for tooling, flow control elements, and exotic material components in downhole or high-heat systems.

- Advanced Fabrication – Certified welding, laser and waterjet cutting, forming, and finishing for heavy-gauge enclosures, pipe systems, and custom energy infrastructure components.

- Integrated Assembly & Testing – Custom assembly solutions for energy modules and subsystems with pressure testing, torque verification, and full traceability for compliance with industry standards.

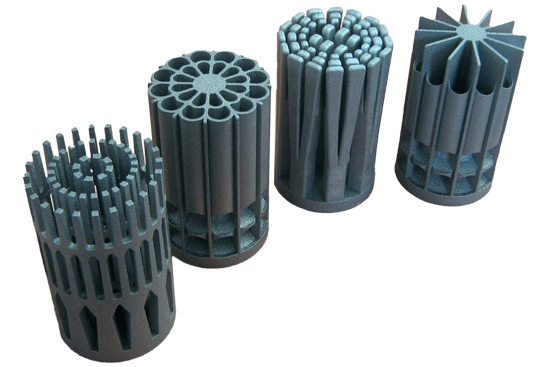

- Metal Additive Manufacturing – Industrial-grade metal 3D printing for rapid prototyping, tooling inserts, and complex geometries, enabling weight reduction, part consolidation, and design flexibility in extreme environments.

Start Your Next Energy Project with BTX

Whether you're sourcing precision components or need a certified energy partner, our organizations have the tools, talent, and technology to deliver.

![]()

ERA brings 5 Axis and Horizontal milling with multi pallets for dedicated set ups and lights out machining capabilities, offering turning, milling, brazing, EDM, assembly and grinding.

![]()

Gen-El-Mec Associates specializes in complex milling and turning for prototype, short-run and long-run production utilizing innovative machining techniques, state of the art equipment and stringent quality control.

![]()

i3DMFG specializes in additive manufacturing, particularly Direct Metal Laser Solidification, with expertise and capacity to support both development and production requirements.

![]()

A1J Technologies is a one-stop machine shop specializing in precision machining, advanced laser applications, and rapid-turnaround parts cleaning.

Chandler Industries combines precision machining with sheet metal fabrication, welding, complex assembly, and other processes to deliver comprehensive solutions.

![]()

Addison Precision Manufacturing is a top-tier contract manufacturer that excels in producing high-precision machined components.

Let’s Power the Future — Together

From turbines and reactors to battery systems and next-gen renewables, BTX Precision supports the world’s most critical energy platforms. Partner with us to produce components that last — with precision you can trust.