Full-Service Metal Fabrication for Complex Assemblies

BTX Precision offers comprehensive metal fabrication capabilities to support the production of custom components, subassemblies, and structural elements for high-performance applications.

Where Custom Metalwork Meets Industrial Scale

From precision sheet metal forming and welding to mechanical assembly and testing, our vertically integrated fabrication services are built to support industries like aerospace, defense, transportation, energy, and industrial automation.

Whether you need a single bracket or a multi-component enclosure, BTX delivers fabrication solutions with consistency, scalability, and speed.

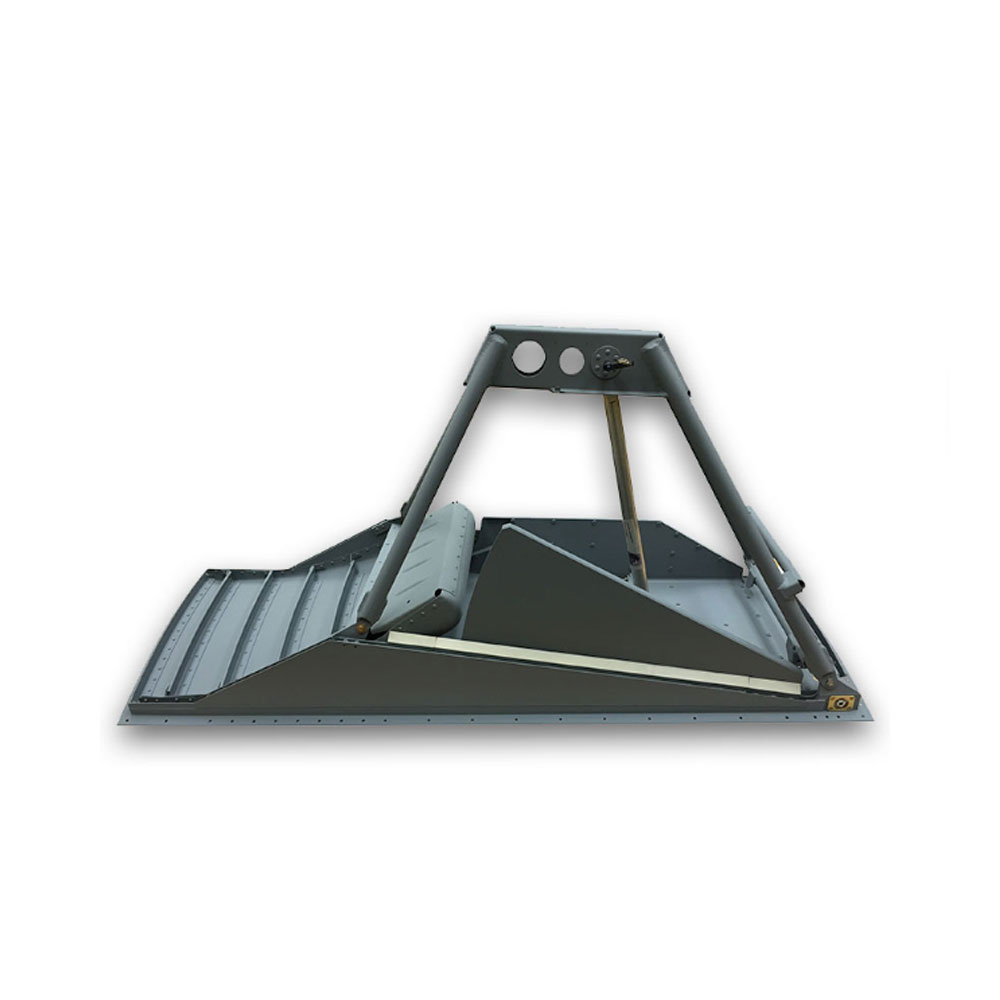

Aircraft Door Assembly

Precision Forming, Welding, and Assembly

Our fabrication teams specialize in producing tight-tolerance, production-ready metal assemblies using high-quality materials and controlled processes. With in-house forming, CNC punching, MIG and TIG welding, and mechanical fastening, we can handle everything from single-part runs to complex, multi-step assemblies.

Our capabilities include:

- Precision bending and forming

- Sheet metal punching and laser cutting

- Certified MIG, TIG, and spot welding

- Hardware insertion and mechanical assembly

- Tapping, grinding, and finishing operations

- Custom fixturing and support for short or long runs

Welding

BTX offers a full range of welding capabilities including MIG, TIG, spot, and robotic welding to support structural, cosmetic, and high-integrity weldments. Our team is skilled in working with a wide variety of metals and part sizes, delivering consistent, repeatable welds that meet both strength and appearance requirements for demanding industries like aerospace, transportation, and medical.

Laser Cutting

Our laser cutting systems provide fast, precise, and highly repeatable profiling for flat and tubular materials. With the ability to handle thin-gauge metals through thick plate, BTX’s laser fabrication services enable clean edges, tight tolerances, and complex geometries — perfect for brackets, enclosures, and high-volume production components.

Waterjet Cutting

We use high-pressure waterjet cutting to machine a wide range of materials — including metals, composites, and non-conductive substrates — without introducing heat-affected zones. This cold-cutting process is ideal for thick or heat-sensitive materials, and allows for tight nesting, intricate profiles, and minimal post-processing.

Bending

Our precision forming and bending capabilities support a wide variety of part geometries and thicknesses. From complex multi-plane bends to high-volume sheet metal parts, BTX uses CNC press brakes and custom tooling to ensure dimensional accuracy, repeatability, and efficient production workflows.

Complex & Mission-Critical Industries

Aerospace & Defense

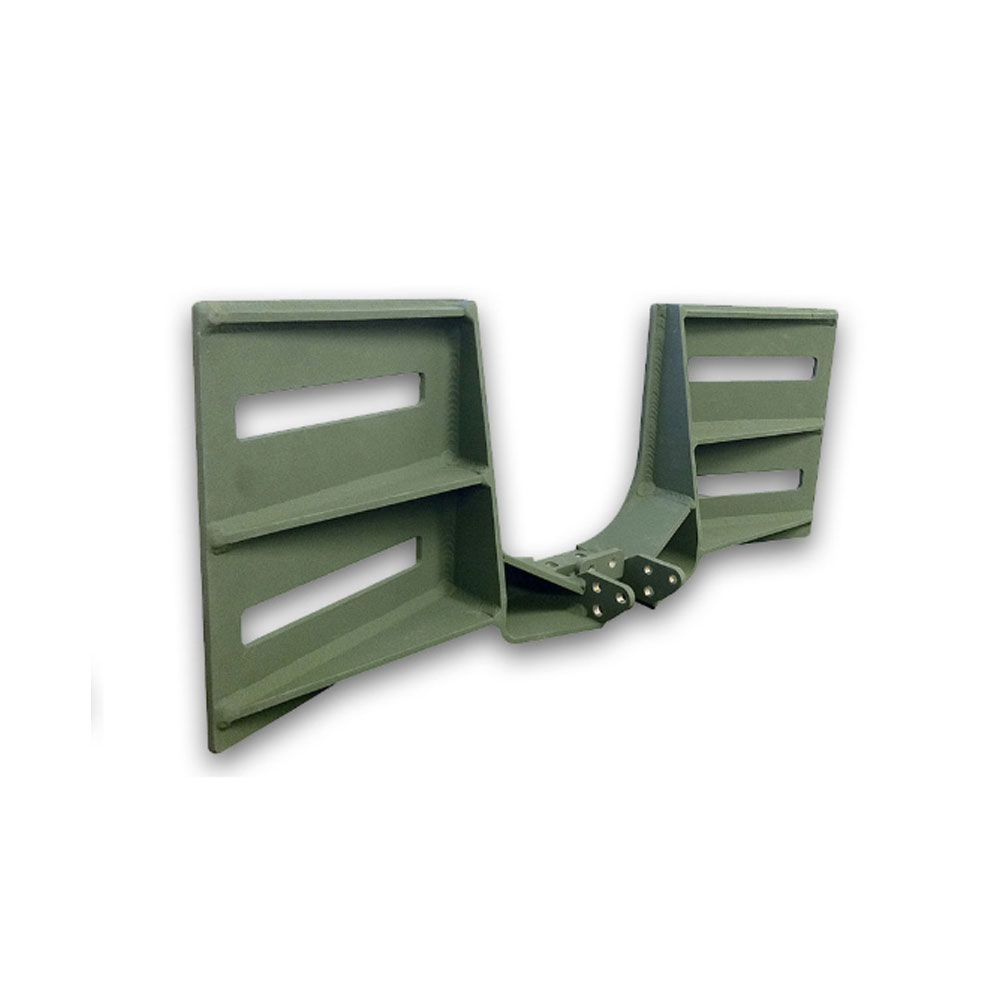

Mounting brackets, ground support structures

Medical

Diagnostic system enclosures, structural housings

![]()

Semiconductor

Precision enclosures, chassis, and component mounts for ultra-clean, contamination-sensitive environments.

Space

Lightweight structural brackets and ground support assemblies built for vacuum, vibration, and launch conditions.

Start Your Fabrication Project with BTX

Proudly Made in the USA | Responsive. Reliable. Precise.