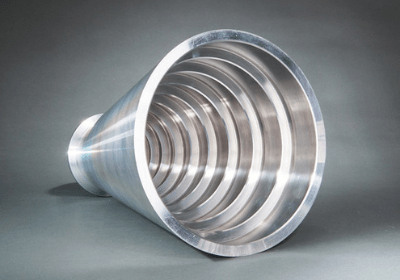

Precision Turning for Complex, High-Performance Parts

BTX Precision provides advanced CNC turning solutions to meet the demands of mission-critical industries

Unmatched Expertise in High-Precision Turning

BTX Precision provides advanced CNC turning solutions to meet the demands of mission-critical industries. Across our network of manufacturing organizations, we produce high-precision turned components for aerospace, medical, defense, energy, and transportation applications — consistently achieving tight tolerances, smooth finishes, and high repeatability.

200+ Turning Machines

Top Machining Platforms (Nakamura, Mori Seiki, Doosan)

Maximum OD Size: 94in

Min OD Size: 0.039in

Tolerance Threshold: +/- 0.0001”

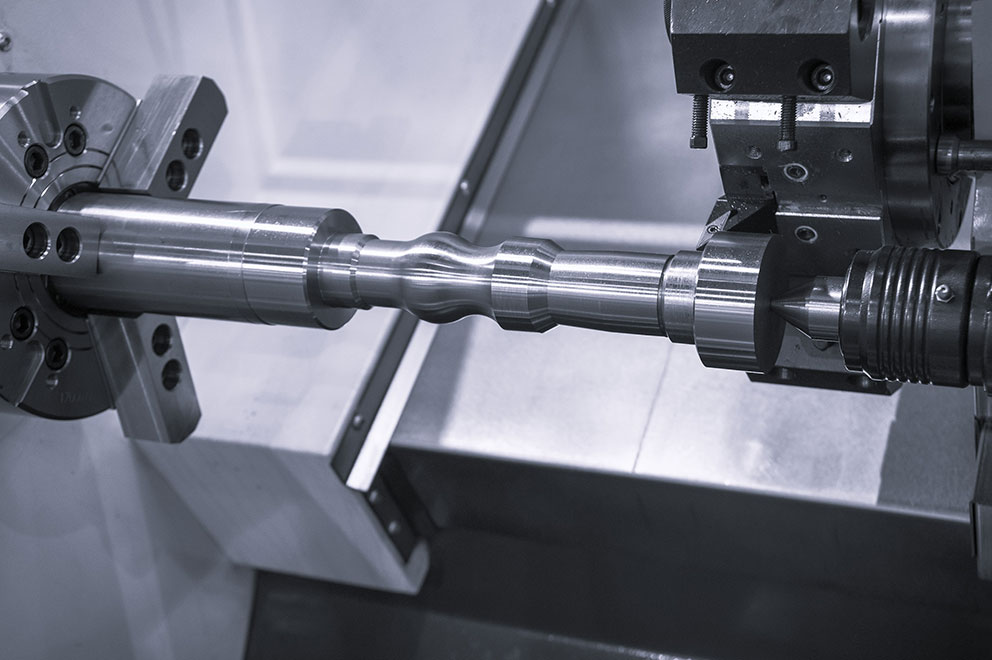

Multi-Axis CNC Turning

Our CNC turning platforms range from 2-axis lathes to multi-axis mill-turn machines with live tooling and sub-spindles. These configurations allow us to complete complex parts in fewer setups — reducing cycle times, increasing part accuracy, and improving overall efficiency.

We support:

- High-speed precision turning

- Complex contouring and threading

- Live tooling for simultaneous milling

- Bar-fed automation for high-volume runs

- Tight concentricity and roundness control

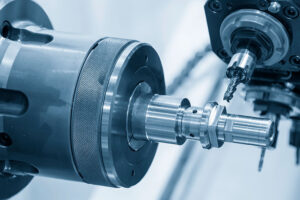

- Swiss CNC Machining micro precision

Versatile Materials for Metals, Alloys, and Engineered Plastics

We perform precision turning operations in a wide range of work materials, including high-strength alloys, stainless steels, aluminum, heat resistant alloys and engineered plastics. Our expertise supports demanding applications across an array of industries and part configurations.

- Aluminum, Copper, Brass

- Alloyed Steels

- Carbon Steels

- Stainless Steels

- Nickel Alloys

- Titanium Alloys

- Thermoplastics

Turning for Complex & Mission-Critical Industries

Aerospace & Defense

Fittings, bushings and connector components

Medical

Medical implants and instrument handles

![]()

Semiconductor

Semiconductor vacuum hardware and alignment pins

Space

Fasteners and thermal system connectors

Built for Production at Scale

BTX organizations offer robust turning capacity designed to support both short-run and high-volume production. With automation-ready systems, bar feeders, and standardized workflows, we help reduce lead times and drive cost efficiency without compromising precision.

- Lights-out machining and unattended operation

- Consistent part quality across lots

- Flexible capacity across multiple facilities

- Integrated inspection and process monitoring

- Turnkey solutions for high-volume OEM programs

State-of-the-Art Equipment for Turning

Swiss CNC

Ideal for small, high-precision components, Swiss CNC machines offer exceptional accuracy and efficiency for complex, slender parts in high volumes.

Mill Turn

Mill-turn machines combine turning and milling operations in a single setup, reducing cycle times and increasing precision for intricate, multi-featured parts.

Turning

Our advanced CNC lathes deliver consistent, high-speed performance for a wide range of round and cylindrical components across industries.

Partner with BTX Precision for your next Turning project

Proudly Made in the USA | Responsive. Reliable. Precise.